Understanding Load Capacities - Choosing the Right Forklift for Heavy Lifting

Forklifts play a crucial role in moving heavy loads efficiently and safely in warehouses and industrial operations.

However, not all forklifts are created equal, and selecting the right one for your specific needs requires a clear understanding of load capacities.

Choosing a forklift with an inadequate load capacity can lead to inefficiencies, increased wear and tear, and even dangerous workplace accidents.

In this guide, we'll break down everything you need to know about forklift load capacities and how to select the right machine for heavy lifting.

What is Load Capacity?

Load capacity refers to the maximum weight a forklift can safely lift at a specific load center. The manufacturer provides this rating (and is often listed on the forklift's nameplate).

Exceeding this capacity can compromise the machine's stability, making it prone to tipping over and damaging the equipment and the cargo.

Key Factors That Affect Forklift Load Capacity

Load Center

The load center is the distance from the load's center of gravity to the forklift's backrest. For most forklifts, a standard load center is typically 24 inches. If the load center extends beyond this, the effective lifting capacity decreases.

Forklift Type and Design

Different forklift models have varying load capacities based on their construction and intended use. Counterbalance forklifts, reach trucks, and heavy-duty forklifts have unique lifting capabilities.

Attachments

If your forklift has attachments such as side shifters, clamps, or fork positioners, these can reduce the effective load capacity due to added weight and shift in the center of gravity.

Mast Height and Tilt

The higher the mast extension, the lower the forklift's effective load capacity. Tilting the mast backward slightly can improve stability when carrying a heavy load.

Tire Type and Condition

The type of tires (pneumatic vs. cushion) and their condition also affect the weight a forklift can handle. Pneumatic tires provide better stability on rough terrain, while cushion tires are ideal for smooth surfaces.

Choosing the Right Forklift for Heavy Lifting

Selecting the right forklift for your operations is crucial to maintaining productivity and safety. Here are some essential considerations when determining the proper one.

Determine Your Load Requirements

- Assess the average and maximum weight you need to lift daily.

- Consider the size, shape, and stability of the loads.

- Ensure the forklift you choose has a higher capacity than your heaviest load to allow for variations in load center and potential add-ons.

Understand the Forklift's Load Capacity Chart

Every forklift has a capacity chart that details how much weight it can lift at different load centers and mast heights. Always check this chart before making a purchase or rental decision.

Selecting the Right Type of Forklift

Depending on your operation's needs, you may require a forklift that has specific capabilities.

- Counterbalance forklifts – Ideal for standard warehouse applications and lifting heavy loads with stability.

- High-capacity forklifts – Designed for construction, heavy manufacturing, and shipping industries.

- Telescopic forklifts – Useful for lifting loads to great heights while maintaining stability.

Evaluate the Operating Environment

- A cushion tire forklift may be the best option if you work indoors on smooth floors.

- A pneumatic tire forklift is more suitable if your operations involve outdoor or uneven terrain.

- Narrow aisle forklifts or reach trucks are optimal for warehouses with tight spaces and high-racking systems.

Consider Forklift Attachments

Attachments such as clamps, rotators, and fork positioners can improve operational efficiency and impact load capacity. Ensure the forklift's adjusted capacity with the attachment still meets your needs.

Common Mistakes to Avoid

Even with the right forklift, mistakes in handling and selection can lead to serious consequences. While each scenario presents its unique challenges, there are some common pitfalls to remember while selecting and operating the equipment.

- Overloading the forklift – Always stay within the manufacturer's specified load capacity.

- Ignoring load center variations – A longer or unbalanced load can drastically reduce the lifting capacity.

- Using the wrong attachments – Not accounting for the weight and impact of attachments can lead to capacity miscalculations.

- Failing to train operators – Even the best forklift is ineffective without properly trained operators who understand load-handling principles.

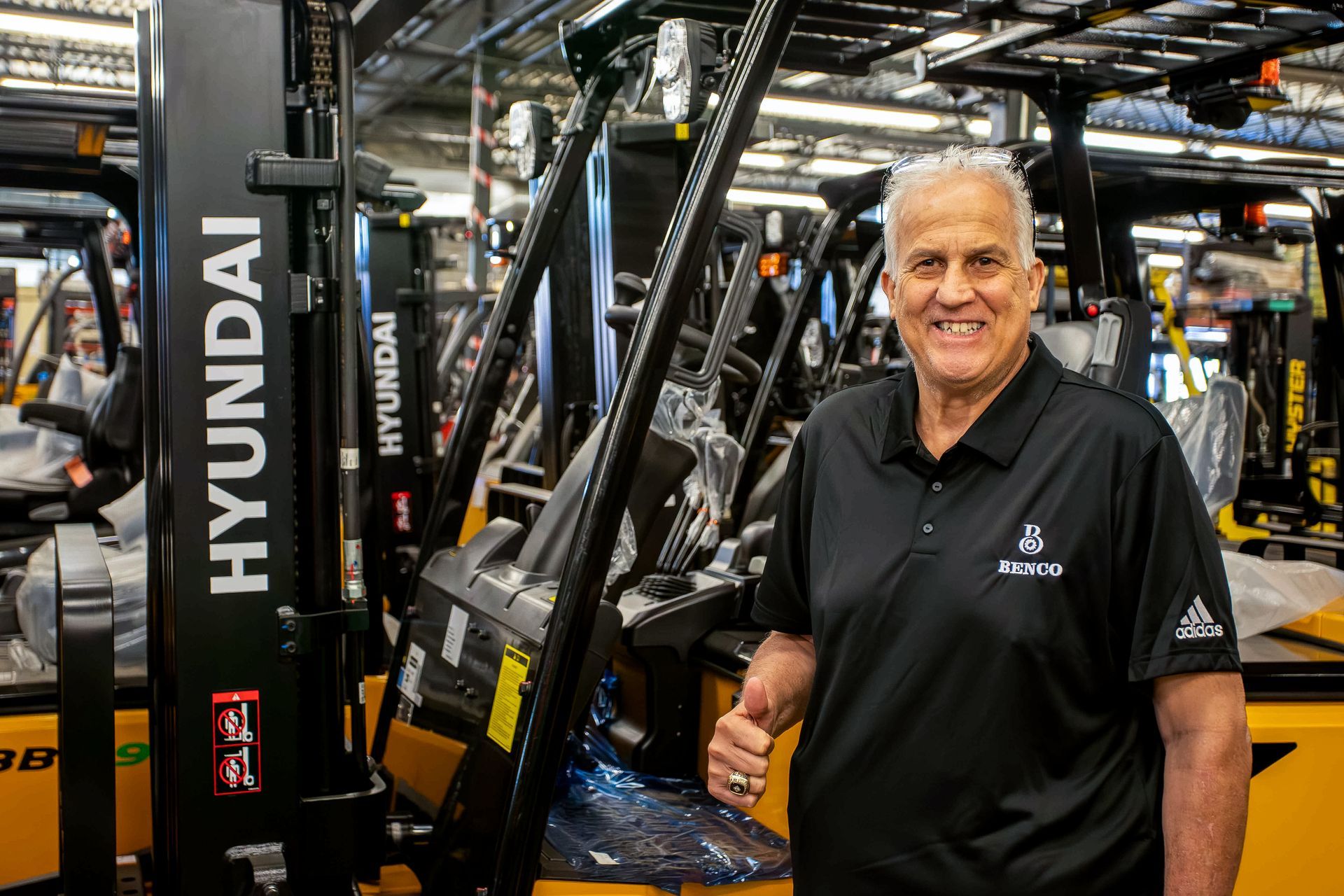

Work With Benco Industrial Equipment

Choosing the right forklift for heavy lifting requires a thorough understanding of load capacities, load centers, and environmental factors.

Selecting the right equipment, adhering to safety guidelines, and ensuring proper operator training can improve efficiency and maintain workplace safety.

Investing in the right forklift will maximize productivity and minimize operational risks, whether you're managing a warehouse, manufacturing facility, or construction site.

Our Benco Industrial Equipment team offers personalized assistance and consultation to help you find the best solutions for your warehouse needs.

Contact us today to explore our range of industrial equipment and services and take the first step toward improving your warehouse operations.