Improving Warehouse Efficiency (Without Expanding Your Footprint)

As warehouses grow, space often becomes a limiting factor. Increasing order volumes, broader product lines, and faster fulfillment expectations can quickly push facilities to their limits.

While expanding a warehouse may seem like the obvious solution, it is also costly, time-consuming, and disruptive to daily operations.

Fortunately, many warehouses can significantly improve efficiency without adding square footage.

The key lies in making better use of existing space and optimizing workflow to support productivity, safety, and scalability.

Start With Layout and Flow

Warehouse efficiency begins with layout. Poorly organized layouts create unnecessary travel time, congestion, and bottlenecks, slowing operations and increasing labor costs.

Evaluating how inventory, equipment, and personnel move through the facility often reveals opportunities for improvement.

Key Areas to Assess

- Reducing travel distance between receiving, storage, picking, and shipping zones

- Improving aisle alignment and spacing to support smoother equipment movement

- Separating pedestrian traffic from forklifts and other material handling equipment

Even small layout adjustments, such as relocating high-volume SKUs closer to shipping or reorganizing pick paths, can lead to noticeable improvements in daily operations.

Using Vertical Space More Effectively

Many warehouses underutilize vertical space, leaving valuable capacity untapped. Shelving, pallet racking systems, and mezzanines allow operations to increase storage density without expanding the building footprint.

When properly designed, vertical storage solutions improve organization, maintain accessibility, and support safe equipment operation.

Pairing these systems with the right material handling equipment ensures that inventory remains easy to access while maximizing available cubic space.

Equipment Selection Supports Efficiency

The right equipment plays a critical role in warehouse performance. Equipment should be selected based on aisle widths, ceiling height, load requirements, and usage patterns, not just upfront cost.

Choosing equipment that fits the environment reduces maneuvering challenges, minimizes delays, and supports safer operation throughout the facility. Well-matched equipment also helps protect infrastructure, reduce maintenance costs, and improve operator confidence.

Custom Installations Solve Unique Challenges

Every warehouse has unique constraints, from irregular building layouts to specialized inventory requirements. Custom installations allow operations to adapt equipment and infrastructure to specific needs.

Tailored solutions can address space limitations, improve workflow efficiency, and eliminate inefficiencies that standard setups may not resolve. Customization ensures that every part of the facility supports the operation's goals.

Continuous Improvement Drives Results

Warehouse efficiency is not a one-time project. As order volumes change and business needs evolve, regular evaluations help identify new opportunities for improvement.

By focusing on layout optimization, vertical storage, equipment selection, and custom solutions, warehouses can increase productivity, enhance safety, and expand capacity (without expanding their footprint).

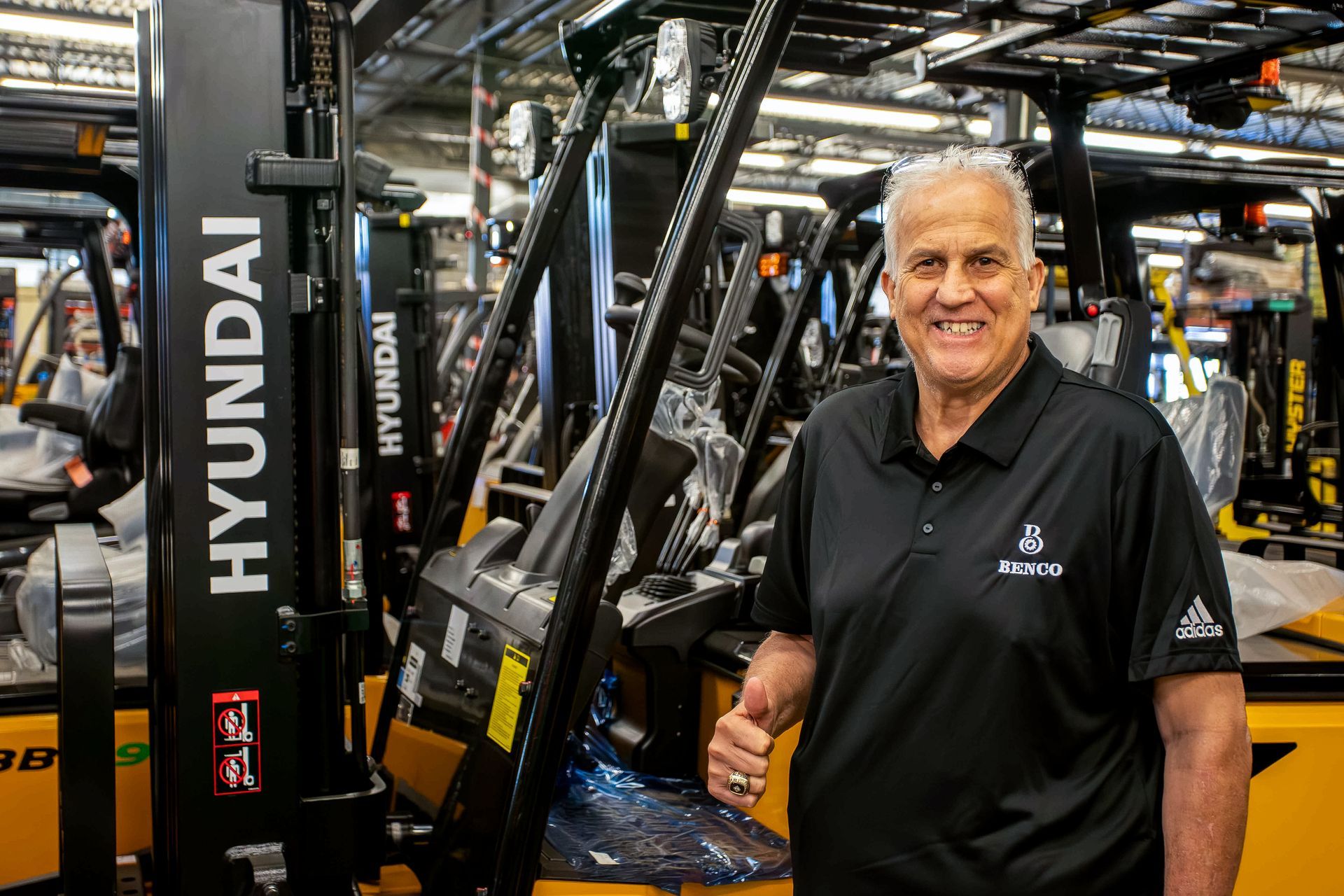

Partner With Experts Who Optimize Warehouse Performance

Improving warehouse efficiency without expanding your footprint requires the right combination of planning, equipment, and execution.

At Benco Industrial Equipment, we help warehouses do exactly that by providing material handling equipment, storage solutions, and custom installations designed to fit your space and workflow.

From evaluating layouts and selecting the right equipment to designing racking systems and supporting long-term operational needs, Benco works alongside your team to create practical, scalable solutions.

If your operation is looking to increase capacity, improve safety, or streamline workflow without costly expansion, Benco Industrial Equipment can help you make the most of the space you already have.

Contact our support team to learn more about how we can enhance and optimize your warehouse operations.